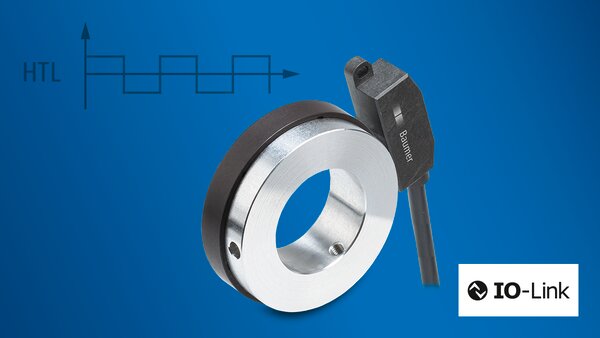

Electrical and mechanical integration of encoders has become much easier and more economically viable in recent years, and the new, bearing-less, EB200E encoder from Baumer is proving this to be correct. In addition to being the first smart incremental bearing-less encoder with IO-Link on the market, the EB200E can be compactly integrated on any axis without complex adaptation of the mechanics . The interface reduces the cost and effort of cabling, with a speed monitoring function replacing additional hardware components.

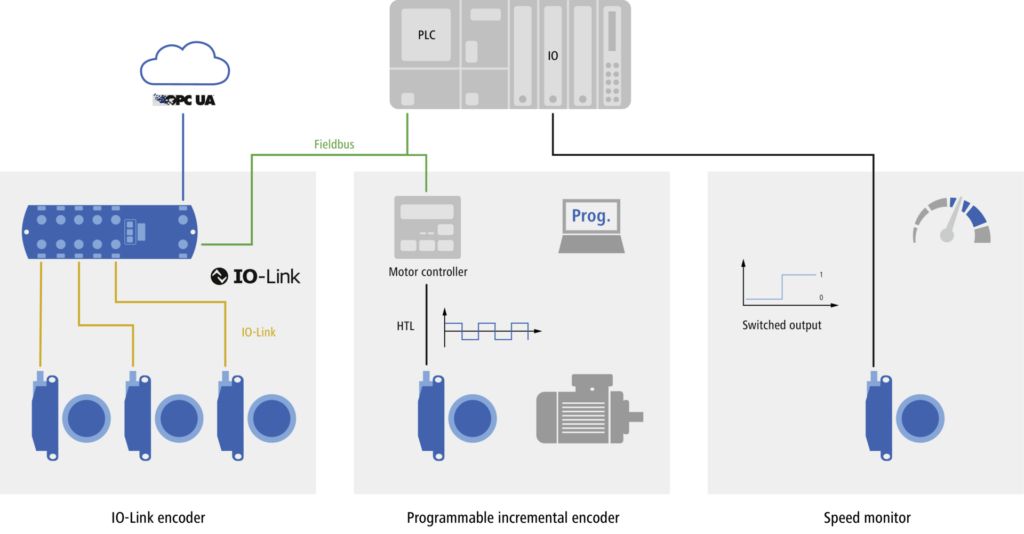

The IO-Link interface allows for up to 8 encoders to be connected to an IO-Link master by cost-effective standard cables. This way, EB200E opens up completely new areas of application: Encoder parameterization is via IO-Link. This interface enables parameterization of two switching outputs to act as a speed monitor for overspeed, speed range, standstill or direction of rotation. Furthermore, EB200E also delivers conventional HTL signals.

With a shallow installation depth of 12 mm and flexible shaft diameters, the bearing-less encoder integrates into the machine design in a space-saving way. Thanks to non-contact sensing between sensor head and magnet ring, the encoder endures dirt, shock or vibration. Also the new Baumer Sensor Suite supports plant engineers as convenient PC tool for intuitive parameterization and data visualization.