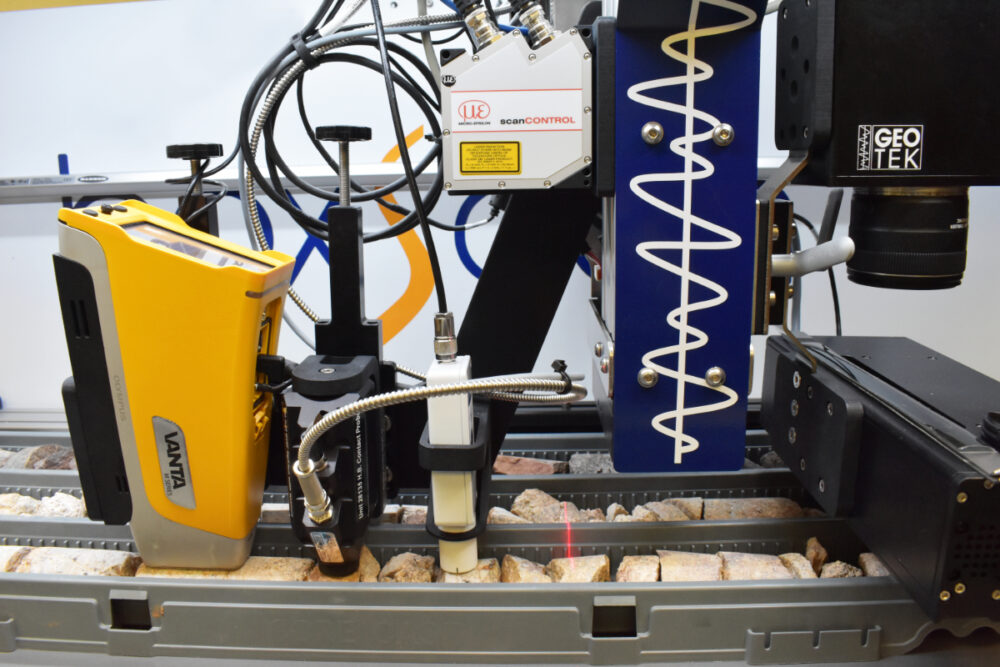

Geotek Ltd. (UK), a specialist in high resolution, non-destructive analysis of geological cores, has chosen to use a 2D/3D laser profile sensor from Micro-Epsilon on its automated, modular, multi-sensor core scanning platform, BoxScan.

The laser sensors are being used to determine the types of rock within the core samples and have proven to be rugged and reliable out in the field, as well as easy to integrate with the BoxScan machine platform.

Based in Daventry, Northamptonshire, Geotek Ltd. has been supplying its range of Multi-Sensor Core Loggers (MSCL) systems for over 20 years, using a suite of geophysical and geochemical sensors aimed at non-destructive core analysis. MSCL systems can collect a wide range of multi-parameter data from soft unconsolidated sediment in plastic liners and unlined rock cores with flexibility, accuracy and efficiency. Applications vary from users in academic and research, to industrial mining, hydrocarbon and offshore geotechnical sectors.

Opportunity to Automate

BoxScan was developed to solve the often resource-draining practicalities of acquiring laborious handheld logging measurements using pXRF, NIR or cameras. Geotechnical and geochemical parameters of rock core samples are acquired automatically and simultaneously in a single operation using the field deployable BoxScan.

Users are able to choose the most fit-for-purpose multi-sensor suite for their project thanks to BoxScan’s modular set up. Through the use of dedicated acquisition software, scanning parameters for each core sample box or even each metre of core can be amended so that frequency of measurement, type of measurement, or even integration time of measurement can be optimized as required for the project.

BoxScan is designed to operate in the field to provide near-time results and has a small enough footprint to easily be transported to remote locations. Only one field technician is needed to operate the machine and up to six different datasets can be acquired without manipulating a sensor, reducing both disturbance of the core material and human error in the measurement.

A ‘Sensor-ble’ Choice

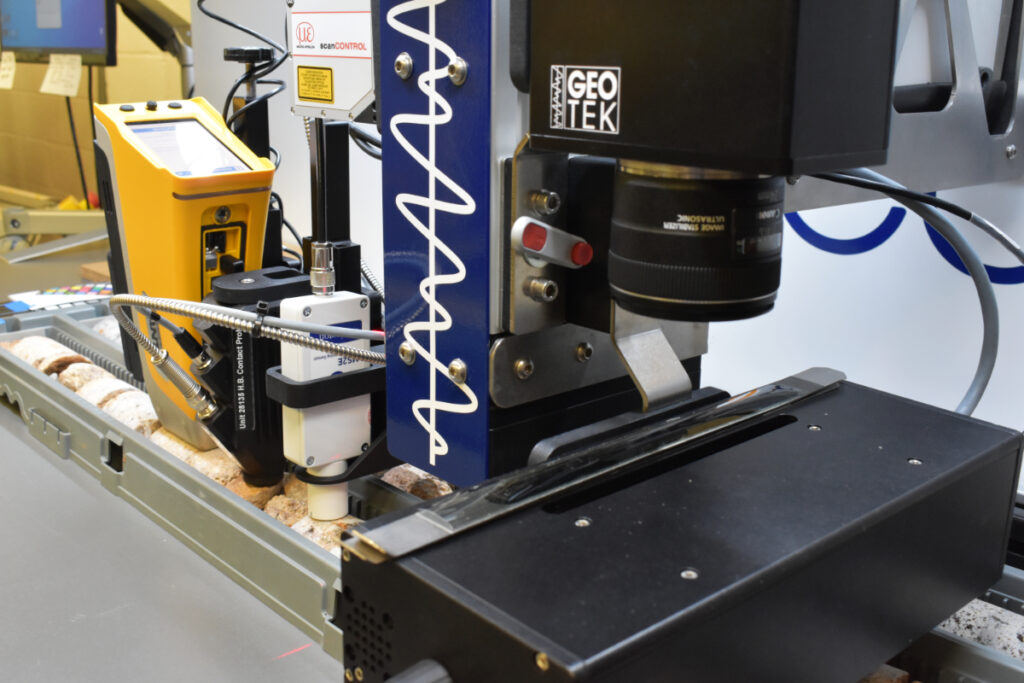

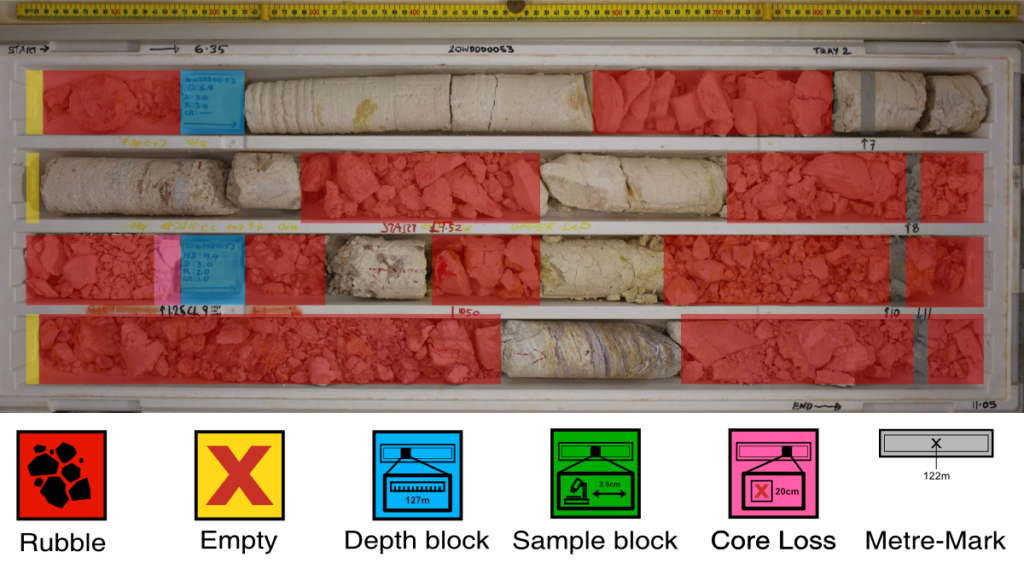

Micro-Epsilon’s scanCONTROL 2900-100 laser profile sensor is mounted on the motorized sensor arm of BoxScan. The sensor acquires a 3D point cloud by scanning over the surface of the core samples in the boxes. BoxScan uses these laser images to segment the solid, fractured and rubble rock. The lengths and positions of the core in the box forms the base data that enables curation of the image and point data. The laser sensor acquires a range of parameters from the core surface including height, reflection width, and moment, which show interesting textual information from the surface of the rock.

James Shreeve, Sales & Marketing Manager at Geotek Ltd (UK) comments: “Laser scans are acquired ahead of point measurements and wet core photography. Pixel size for the laser sensor is dependent on acceptable scan times. We choose 200µm per pixel as an acceptable resolution. Core curation is performed from the height map and the core box image. By using the laser data to interpret the geotechnical parameters of core samples in this way, our BoxScan customers can combine mineralogy and chemistry within the rock with rock quality leading to vital clues for vectoring towards mineral exploration targets.”

Compact, Rugged and Reliable

The scanCONTROL 2900-100 is extremely compact and lightweight. The controller and electronics are integrated directly in the sensor. The sensor has a measuring range of 100mm, a profile resolution of 1,280 points across the line width, a profile frequency of up to 300Hz, and line linearity of 12µm.

James Shreeve states: “We chose the scanCONTROL 2900 sensor for several reasons. It was a combination of resolution, communications protocols and ease of integration. We normally choose sensors from third parties based on a good solid SDK [software development kit], good relationships with the supplier whereby it’s very well understood how we integrate their sensor onto our platforms and then obviously the measurement specifications of the laser sensor. In other words, will it give us the required resolution and can it measure the types of features and parameters we need it to?”

He continues: “Form factor of the laser sensor was also important for the BoxScan platform. The motorised sensor arm, where all the machine sensors are installed, is quite compact and so form factor of the laser sensor, and the fact it has an integral controller, was also critical.”

According to James, the laser sensors also need to be rugged and reliable. He explains: “BoxScan only uses sensors that are capable of being deployed out in the field. The whole purpose of BoxScan is to be able to perform reliably under tough conditions. For example, we have BoxScan systems in the Gobi Desert, the Australian outback, Turkey and in the Central region of Brazil. So all the sensors need to perform reliably and must withstand high and low temperatures, dust, dirt, and so on. You simply cannot have an unreliable BoxScan system if it’s being used in a remote desert region.”

SDK and Easy to Integrate

The scanCONTROL 2900-100 is equipped with a Gigabit Ethernet interface for transferring profile data, as well as a multi-purpose connector for RS422, Digital In (HTL/TTL), power supply and synchronization. Configuration of the sensor is carried out using a supplied software program, which enables the device to be configured to a unique IP address. A Modbus protocol (supported via Ethernet and the RS422 interface) also enables direct connection between the sensor and any common PLC. The software development kit (SDK) and function library (LLT.dll) supplied as standard with the sensor provide the user with a communications platform that offers maximum flexibility and performance via direct integration with most common programming languages.

As James Shreeve puts it: “In selecting the scanCONTROL sensor, it was very important how it integrates with BoxScan. The SDK is the most important factor for us and gives us the ability to control the sensor in our normal scanning operations, which adds the most value. Connectivity and the physical connections that we use must be able to withstand long cable chain lengths, which is also important. But ultimately it’s the software communication protocols, a good SDK and application interface that are most valuable to us.”

On the subject of supplier relationships, James Shreeve enthuses: “In truth, everyone here at Geotek who has dealt with Micro-Epsilon, believes they’re a very professional bunch. They’ve also delivered sensors on time and are very open to any new applications we discuss with them. They’ve given us valuable feedback on the different types of sensor technologies that are available for different machine applications, which means they give us the right sensor technology for the application, rather than pushing the sensor product they want to sell the most of. So from our perspective, they’ve been an excellent supplier.”