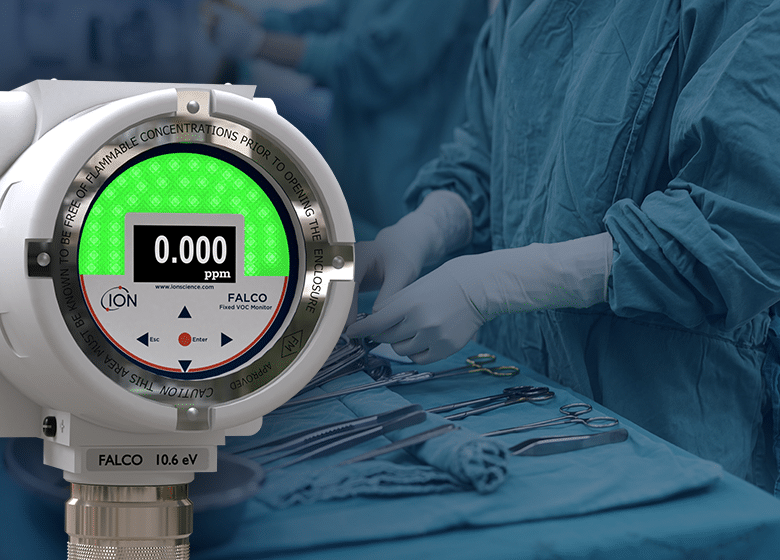

ION Science has provided a complete VOC monitoring solution with the Falco, providing customers with complete monitoring assurance regarding VOCs (Volatile Organic Compounds) at every stage of production.

The Falco needs little in the way of maintenance and will reliably record data on VOC exposure wherever needed. Additionally, it is enabled with both Modbus and 4-20mA output protocols for site-wide networking capabilities. This gives total confidence that all equipment is sterilized within the legal requirements.

Not only does the Falco fixed fenceline detector provide complete assurance across sites of any size, but other benefits also include a user-friendly interface and an easy fit and service design. The internal lamp comes with a minimum one-year lifespan, giving customers reliability and peace of mind.

The Falco has four detection ranges available:

- 0–10ppm

- 0–50ppm

- 0–1,000ppm

- 0–3,000ppm

One of the most important areas for VOC monitoring is the sterilization and packaging of medical equipment. It is common practice for manufacturers to use ethylene oxide in decontaminating products prior to leaving the site. While this is a highly effective method, it is a harmful VOC and needs careful monitoring when in use. It is critical to reduce the potential exposure to staff, product and even end-users, and therefore monitoring the levels of ethylene oxide that are used to remove potential contaminants, must be done with a safety-first approach prior to distribution.

In medical environments such as hospitals there is also a potential VOC hazard. Toluene is often used in medical applications for the preparation of instruments. As well as medical environments, laboratories commonly reported the VOC hazard in a 2015 study. The study revealed that staff coming into contact with toluene were in some cases receiving up to 16 times higher doses of VOC exposure than other staff who didn’t work in these spaces. Appropriate VOC monitoring, such as fixed sensors in these workspaces and buildings, would have been able to detect the hazardous levels and ultimately reduce the health risk to staff.

For manufacturers that handle large volumes of products or operate across multiple sites, ethylene oxide may be used frequently and at multiple stages of the manufacturing cycle. This requires not only highly sensitive levels of detection to ensure that the correct levels are being adhered to at particular stages, but also there is a requirement to have many sensors on and around the site, so any potentially harmful levels are detected quickly.