Celera Motion has announced an innovative new device for precise angle measurement. The IncOder CORE is a compact, ultra-lightweight inductive angle encoder, ideal for a variety of surgical, medical and industrial robotics.

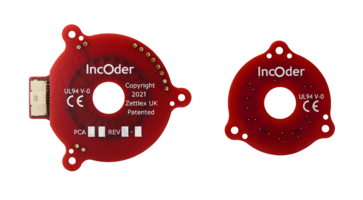

IncOder CORE is a non-contact device featuring the robust and reliable position sensing technology of IncOder — fully contained in a stacked printed circuit board (PCB) kit that reduces OEM system mass.

“While IncOder remains the market leader in harsh environment position sensing, IncOder CORE delivers superb performance in an extraordinarily lightweight package,” said Mike Mainvielle, Vice President of Product Management and Marketing for Celera Motion. “Like all IncOder devices, it’s easy to install and uses proven technology that provides worry-free, accurate measurements 24/7.”

IncOder CORE is well suited for integration into rotary joints. The position sensor utilizes a unique field-proven inductive technique, delivering highly repeatable, reliable, temperaturestable performance.

IncOder CORE is designed primarily for segments including surgical robotics, medical robotics, rotary actuators and industrial robotic systems. It is now offered in a compact 44mm size, with a 10.4mm thru bore and options for customization available. More sizes will be coming soon.

Features of the IncOder CORE include:

- No precision installation tolerances

- No calibration required

- An ergonomic hollow bore design

- Bearingless

- Absolute position feedback

- Immune to contamination

Benefits of the IncOder CORE include:

- Reduced system weight and design envelope

- Simple installation

- Reduced OEM production time and cost

- Optimized for use in rotary actuators

- Reliable feedback in demanding applications

- Robust position measurement

IncOder CORE has been optimized for integration into host system mechanics. Each sensor includes a passive rotor target paired with an active stator — both featuring a large thru bore and practical M2 screw mounting features.

IncOder CORE can be configured to output up to 17 bits of absolute digital position data in a range of digital protocol options, including BiSS-C, SSI, SPI and Asynchronous Serial (ASI) outputs. It can be supplied with axial or radial connector options.